Produktbeschreibung

Der HDPE-Kunststoffrohr-Extruder ist eine hocheffiziente und energiesparende Maschine, die zur Herstellung von HDPE-Schutzmantelrohren für Polyurethan (PU)-Schaum-vorgefertigte isolierte Rohrleitungen entwickelt wurde.

Er zeichnet sich durch eine kompakte Struktur, einfache Bedienung, ein automatisches Steuerungssystem, stabile Leistung und eine lange Lebensdauer aus.

Zusammensetzung der Produktionslinie:

-1 Satz Vakuumlader

-1 Satz Trichtertrockner

-1 Satz Hocheffizienz-Einwellenextruder

-1 Satz Vakuumkalibriertisch

-1 Satz Wassersprühtank

-1 Satz Abzugsvorrichtung

-1 Satz Schneidemaschine

-1 Satz Stapler

---Rohrverwendung: die Außenhülle von Wärmeisolationsrohren, die in Fernwärme, Öl, Erdgas und anderen Industriebereichen weit verbreitet ist.

---Rohr-/Manteldurchmesserbereich: 110-1680 mm

Unsere Vorteile

---Hocheffizienz-Extruder liefert einen größeren Ausstoß und stabile Leistung.

---Die Rohrwand ist gleichmäßig und glatt, um Materialverschwendung zu reduzieren, und die Rohrdicke ist einstellbar.

---Kein Kantenbeschnitt erforderlich, einmalige Formgebung.

---Hoher Automatisierungsgrad, kann von einer Person bedient werden, wodurch Arbeitskosten gespart werden.

Detaillierte Fotos

1. Hocheffizienz-Einwellenextruder

---Die Einzelschnecke ist mit einer Barriere- und Mischkopf ausgestattet; neues Modellfass mit Schlitzen (Kanal), beides sorgt für die Sicherheit einer guten Gelierung, einen großen Ausstoß und eine stabile Leistung.

![Energiesparendes HDPE-Mantelrohr-Extrusionssystem mit automatischer Steuerung und stabiler Leistung für die Herstellung von vorisolierten Rohren 4]()

2. Werkzeugkopf

Der Werkzeugkopf besteht hauptsächlich aus Dorn, Halsform, Spiralkörper, Abdeckung, Werkzeugkopfkörper, Bolzen und Heizringen.

Die Innenfläche, die mit Kunststoffmaterialien in Berührung kommt, ist poliert und verchromt, um einen reibungslosen Fluss der Kunststoffmaterialien zu gewährleisten und Rost zu vermeiden. Die Gleichmäßigkeit der Rohrwandstärke kann durch Bolzen eingestellt werden. Die im Werkzeugkopf befestigte Kupferkalibrierhülse dient hauptsächlich dazu, das frische Rohr abzukühlen und den Außendurchmesser des Rohrs zu kalibrieren.![Energiesparendes HDPE-Mantelrohr-Extrusionssystem mit automatischer Steuerung und stabiler Leistung für die Herstellung von vorisolierten Rohren 5]()

3. Vakuumkalibrier Tank

Der Vakuumkalibrier Tank besteht hauptsächlich aus Rahmen, Edelstahlbehälter, Vakuumsystem, Sprühkühlsystem, Positionseinstellvorrichtung. Die Vakuumpumpe evakuiert die Luft aus dem abgedichteten Tank, um das frische Rohr unter Druck zu setzen, um die Kupferhülse zu kalibrieren und den Außendurchmesser zu kalibrieren. Sprühdüsen sprühen Kühlwasser aus allen Richtungen auf die Rohroberfläche, um das Rohr sofort abzukühlen. 4. Abzugsvorrichtung

4. Abzugsvorrichtung

Die Abzugsvorrichtung besteht hauptsächlich aus Antriebsvorrichtung, Schienen, Klemmstruktur, Einstellsystem, Seitenplatte und Fundament Bett. Abzugsketten werden angetrieben von AC-Motor mit Frequenzumwandlungs Steuerung, um sich an unterschiedliche Extrusionsgeschwindigkeiten anzupassen.

Eine automatische Längenmessvorrichtung realisiert das Schneiden in einer eingestellten Länge.![Energiesparendes HDPE-Mantelrohr-Extrusionssystem mit automatischer Steuerung und stabiler Leistung für die Herstellung von vorisolierten Rohren 7]() 5. Staubfreier Schneider

5. Staubfreier Schneider

Es verwendet das Stanzprinzip der Klinge, um staubfreies Schneiden zu realisieren. Es besteht hauptsächlich aus einer Schneidevorrichtung, einer Klemmeinrichtung, einer Struktur-Synchronbewegungs-Vorrichtung und einem Rahmen. 6.Steuerungs System

6.Steuerungs System

Die komplette Linie kann durch SPS gesteuert werden, mit einer guten Mensch-Maschine-Schnittstelle, alle technischen Parameter können durch Berühren des Bildschirms eingestellt und angezeigt werden. Das Steuerungssystem kann nach Kunden Anforderungen entworfen werden.

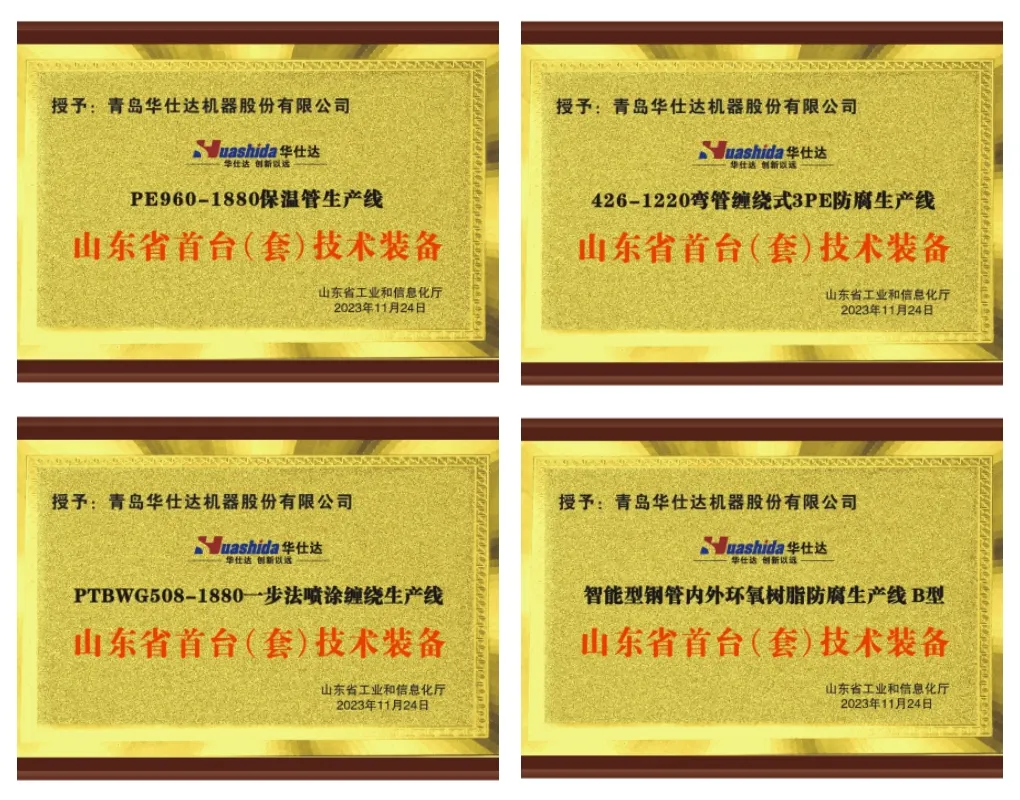

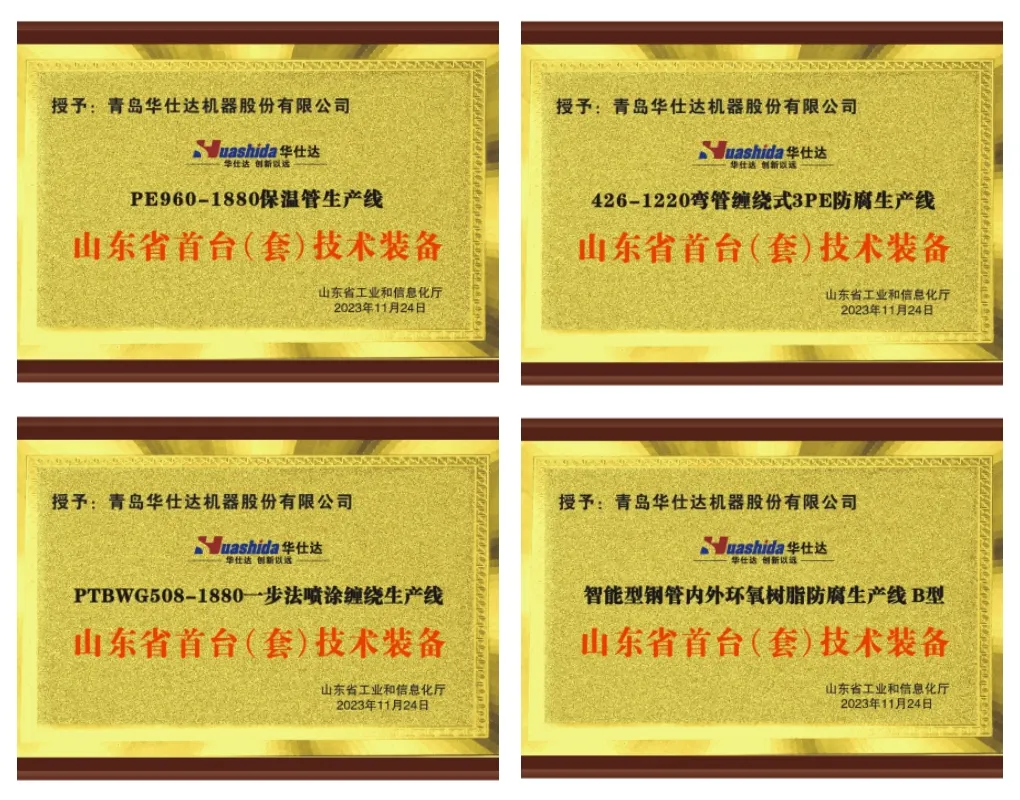

Firmenprofil

Qingdao Huashida Machinery Co., Ltd. ist seit 2003 in der Entwicklung und Produktion tätigvon von Pipeline-Korrosionsschutzgeräten und Rohstoffen. Es ist ein führenderHersteller von wärmeschrumpfbaren Hülse und Ausrüstung in China. Die Marke Huashida wird von in- und ausländischen Kunden bevorzugt. Geräte des Gerätedesigns have our Patents. We bestanden ISO9001, ISO14001Environment, ISO45001 Gesundheitszertifizierung. Bis heute wurden mehr als 500 Sätze von Produktionslinien exportiert nach Russland, Kasachstan, Weißrussland, Ägypten, Iran, Indonesien und anderen Ländern. Huashida-Marke wärmeschrumpfbar Hülse Ausrüstung im Produktionsprozess der kontinuierlichen Zusammenfassung und Aktualisierung hat die vierte Generation von Produkten auf den Markt gebracht. Die gesamte Produktionslinie hat ein vernünftiges Design, intelligente Bedienung, hohe Geschwindigkeit und hohe Effizienz, Energieeinsparung und Stromspar-Material Arbeitskosten. Kontinuierliche Verbesserung des Komponentendesigns gewährleistet eine gleichmäßige Dicke, verbesserte Schrumpfung, Zugfestigkeit und Bruchdehnung. Produktqualität, um die Bedürfnisse verschiedener Pipeline-Korrosionsschutz Bedarfzu erfüllen. Wir haben ein professionelles Kundendienstteam, das Vor-Ort- und Online-Video-Schulungen anbietet und Schulungen. Helfen Sie Kunden, Produktionsprobleme so schnell wie möglich zu lösen.

Unser Team

Zertifizierungen

Internationale Handelsmesse

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!