3pe Antikorrosionsbeschichtungist dasDas Stahlrohr ist durch drei Schicht geschütztSdas Leben von verlängernServiceVon 5 bis 10 Jahren bis 50-100 Jahre.

Die erste Schicht ist Fusionsbindungs -Epoxidschicht (FBE> 100 uM), die zweite SchichtIstKlebstoff (AD) 170 ~ 250 µm,Unddie dritte SchichtIstPolyethylen (PE)Streifen2,5 ~ 3,7 mm.

3pe StahlbeschichtungRohrhatDie Merkmale vonhohe mechanische Festigkeit, ausgezeichnete elektrische Isolationsleistung, Prozessgenauigkeit und Umweltfreundlichkeit.

Anwendung

Die dreischichtigeHDPE -StreifenwicklungProzess mit Epoxidpulverbeschichtung alsuntenSchichtund Bindungskleber als zweite Schicht, IstDieweit verbreitetTechnikIn StahlrohrAntikorrosion Überall auf der Welt. TDas Stahlrohr mit Korrosion werden in Öl-, Gas- und Wasserversorgungsrohrleitungen aufgetragen.

Dreischichtstruktur von 3pe Anti-Korrosionsrohr

Der dreischichtige PE-Anti- -Die Korrosionsstruktur umfasst die untere Schicht mit Fusionsbindungen, die mittlere Schicht und Polyethylen Polymerkleber und PolyethylendraußenSchicht. Das Epoxidpulver ist eine Art thermosettierende ungiftige Beschichtung, die nach dem Festigung die mit hohe Molekulargewicht verankerte Strukturbeschichtung bildet und gute chemische Anti-Anti aufweist- -Korrosion und hohe mechanische Eigenschaften.FDie Einstellung der Epoxidschicht besteht darin, eine kontinuierliche Beschichtung zu bildenUnd um das zu liefernStahlrohroberfläche mit gutem chemischen Widerstand und kathodischem Auflösungswiderstand. Die Funktion des Polymerklebers besteht darin, das Epoxid zu agglutinierenSchicht und diePolyethylendraußenSchicht, die alle drei Schichten miteinander verbindet.Die Polyethylenschicht schützt das Rohr vor Abrieb, Beule und Wasser.

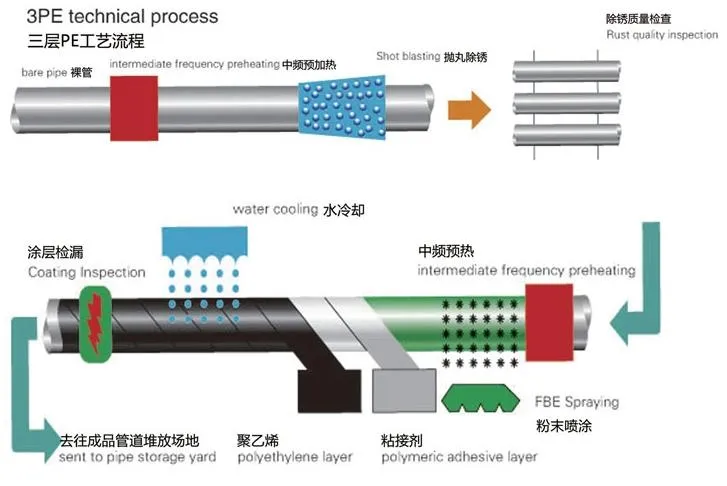

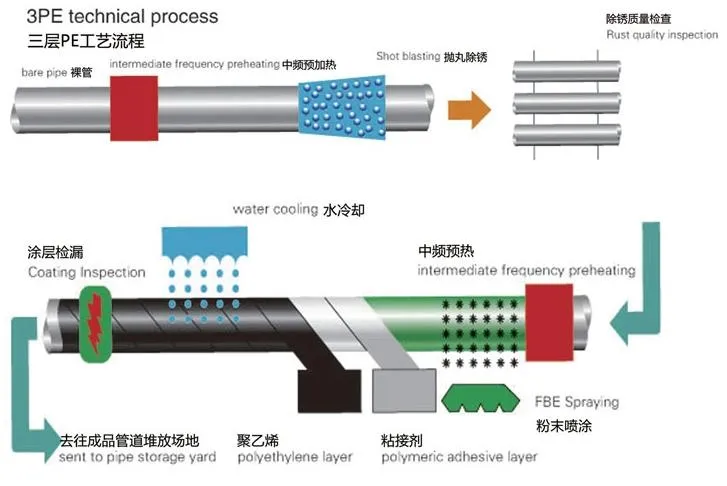

Technologischer Fluss

Laden Sie Rohre hoch → Rohre Förderer → Rostentfernung→Zwischenfrequenzheizung → Epoxypulverbeschichtung →Mittelschicht& PolyethylenStreifenwicklung→WasserKühlung → Rohre Förderer → RohrFase→ Rohre entladen

Sprengmaschinerie

Stahlrohrförderer

FBE -Beschichtungsmaschinerie

PE/PP -Schicht -Wrap -Extruderlinie

Produktparameter

Hauptausrüstung der 3pe Antikorrosionsbeschichtungsverarbeitung

| NEIN. |

Name |

Satz |

| A. Derusting Ausrüstung |

| 1 |

Rohrleitungsausrüstung |

1 |

| 2 |

Schussblastreinigungsmaschine |

1 |

| 3 |

Zyklonstaubsammler |

1 |

| 4 |

Pulsstaubsammler |

1 |

| 5 |

Zentrifugaler Abgasventilator |

1 |

| 6 |

Rostentfernungsausrüstung plc |

1 |

| B. Beschichtungsausrüstung |

| 1 |

Beschichtungsübertragungsausrüstung |

1 |

| 2 |

Wenn Heizgerät |

1 |

| 3 |

Pulversprühgerät |

1 |

| 4 |

Automatischer Ladetrockner |

2 |

| 5 |

SJ-65/30 Extruder |

1 |

| 6 |

SJ-180/30 Extruder |

1 |

| 7 |

Heißem Schmelze -Klebstoff -Extruder sterben |

1 |

| 8 |

PE -Blatt -Extruderkopfform |

1 |

| 9 |

Heißschmelzkleber/PE -Blechbeschichtungsvorrichtung |

1 |

| 10 |

Umweltschutzbeatmung Ausrüstung |

1 |

| 11 |

Kühlsprayausrüstung |

1 |

| C.Plattformausrüstung |

| 1 |

Stahlrohrplattform |

1 |

| 2 |

Übergangsplattform nach der Strecke Entfernung |

1 |

| 3 |

Produktrohrspeicherplattform |

1 |

| 4 |

Hydraulikausrüstung |

3 |

| D.Rillenausrüstung |

| 1 |

PE -Schrägermaschine |

2 |

| 2 |

Hydraulisches Heben und Drehmaschinen |

1 |

| 3 |

Hydraulikausrüstung |

1 |

| 4 |

Plc |

1 |

| E. Komprimierte Luftausrüstung |

| 1 |

Schraubluftkompressor |

1 |

| 2 |

Kalte trockene Maschine |

1 |

| 3 |

Präzisionsfilter |

3 |

| 4 |

Gasspanzer |

1 |

Unternehmensprofil

Qingdao Huashida Machinery Co., Ltd wurde 2003 gegründet. Seit seiner

Inception hat sich Huashida auf Kunststoff -Polyurethan -Isolationsrohre konzentriert

Produktionslinie, 3pe Anti-Korrosionsrohrproduktionslinie, großer Durchmesser

Unterirdische Rohrproduktionslinie und Plastikrohrverbindungen für 20 Jahre.

Wir haben Forschung und Entwicklung immer von großer Bedeutung.

In enger Zusammenarbeit mit der Tsinghua University, der Peking University of

Chemische Technologie, South China University of Technology und Scientific

Forschungsinstitutionen. durch Absorsion fortschrittlicher Technologie nach Hause und

Im Ausland haben wir jetzt einen der drei besten Hersteller der Branche in der Branche in

China.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!